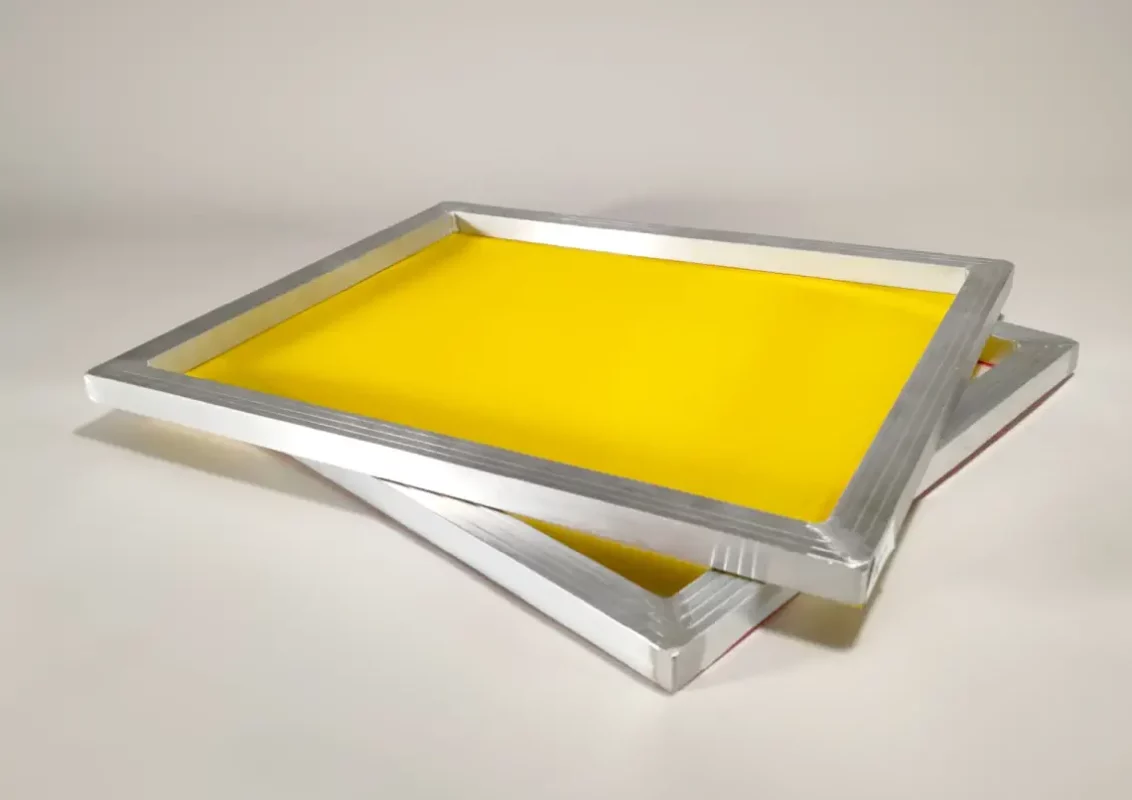

Screen Printing Frames

Professional Aluminum Frames with MEsh and Ready to use

Superior Screen Printing Frames for Every Project

We provide high-quality frames in a range of sizes and mesh kinds to improve your screenprinting. Professional prints on t-shirts, posters, and canvases require the right frame. We can guarantee that you’ll find the ideal equipment to realize your artistic vision thanks to our wide assortment. With our outstanding frames, you can enjoy the satisfaction of stunning screen-printed products. We offer everything you need, from intricate designs to substantial block prints. Every one of our frames is built to guarantee a smooth and efficient screen-printing procedure.

The Right Frame!

DIY MINI KIT: Save 25% now

Use Coupon Code: FJCIRKS81

Unleash your creativity with our versatile screen printing frames!

The choice of the best frame is crucial to the success of screen printing. These frames, which keep the mesh in place, are made of different materials, have variable diameters, and are intended to meet diverse printing requirements. In order to complete your projects with the best results possible, it is imperative that you comprehend the traits and benefits of each type.

Let’s first examine the various materials, such as wood, aluminum, and steel, that can be used to create frames. Depending on the particular needs of your project, each material has a different set of benefits and drawbacks.

As a result of its accessibility and affordability, aluminum frames are a popular option. They are perfect for novices or those on tight budgets because they are relatively lightweight and simple to use.

Aluminum frames are lightweight, sturdy, and resistant to warping. They maintain consistent tension across the mesh, ensuring precise prints every time. While aluminum frames tend to be more expensive than their wooden counterparts, their durability and longevity make them a cost-effective choice in the long run.

Steel frames are the most robust and durable option, offering maximum stability for large-scale projects or heavy use. However, their weight and cost may be prohibitive for smaller projects or those with limited budgets.

It’s crucial to think about the size of the frame for your project in addition to the frame’s construction material. The size of the frame should match the specifications of the printed design. Utilizing a frame that is too narrow could cause the mesh to expand over its breaking point, creating uneven stress and perhaps harming the mesh. On the other hand, employing a frame that is too big for your design can result in wastage of resources and higher expenditures.

The mesh count

The type of T-mesh that will be employed is another factor to consider while selecting a frame. Variable amounts of tension are needed for various mesh counts and materials, and these tension levels must be appropriate for the frame being utilized. For instance, a stronger frame is needed to sustain the required tension for detailed prints at higher mesh counts.

The number of threads per linear inch in the mesh material that is stretched over the frame is referred to as the “T mesh count” in screen printing. The “T” stands for “threads,” and the value indicates the mesh’s density.

A mesh with a greater T-count has more threads per inch, which causes the spaces between the threads to be narrower. Due to the ability to transfer smaller lines and dots onto the substrate, this enables the printing of more complex and detailed designs. When using water-based inks, which have a thinner consistency, higher mesh counts are frequently employed.

On the other hand, a mesh with a lower T-count has more openings between the threads and fewer threads per inch. With this set up, you may print bold designs with thicker inks, including plastisol inks, with higher ink coverage.

It is important to choose the right T-mesh count for a project because it affects the overall print quality and the mesh’s compatibility with the ink and substrate being utilized.

The frames must be properly cared for and maintained in order to yield the finest results. The lifespan of the frame can be extended and the caliber of your prints can be maintained with routine cleaning and examination. In order to avoid warping or damage, it’s also crucial to store frames in a dry, climate-controlled environment.

Conclusion

Selecting the right frame and especially the right T-Mesh-Type for your screen printing project, is critical for achieving optimal results. The choice of material, size, and compatibility with the mesh are all factors to consider when making your decision. By taking the time to understand the various options available and their respective advantages, you can ensure a successful and efficient printing experience. As a beginning screen printer, you can start with a frame in any size prepared with a 54T mesh.